* Results of the scientific study carried out in the winter of 2020-2021 in partnership with the Deschambault Animal Science Research Center.

Introduction

The purpose of this project is to compare the new wintering slipcover designed by Bee Space with other methods currently used by beekeepers.

The current technics used to cover beehives are being questioned because materials used come from the construction industry and are not specifically conceived for the beekeepers’ use. The main problem with these materials is that they present a vapour barrier, which means that they don’t allow the transmission of humidity and water vapour. Humidity can have a negative and even deadly impact on bee colonies if it is not controlled properly. A faulty ventilation of the hive may cause humidity problems and condensation in the internal habitat of the bees. This could result in the decline of the beekeeping equipment and the loss of colonies. If humidity accumulates in the hive, the bees won’t be able to conserve heat and won’t survive throughout the winter (personal communication with Nicolas Tremblay, provincial beekeeping advisor, 2015).

To resolve the humidity problem brought by current methods during outside wintering, Bee Space has created a slipcover with technological textiles that combine the effects of heat conservation, waterproofness, and humidity release. The structure of technological textiles allows the slipcover to breath while keeping bad weather and vermin from coming inside the hive and therefore optimally eliminating the humidity that can accumulate in the colony due to the bees’ winter activities and outside weather conditions. This slipcover is being compared to current methods used.

Methodology

At the end of the 2020 summer, 50 CRSAD colonies with similar strength were selected and divided randomly into 5 experimental groups (n=10 for each group). A HOBO probe, measuring temperature and relative humidity, was installed inside 8 colonies of each experimental group. The probes measured the parameters at a 15-minute interval all through winter.

- Bee Space™ slipcover and hive on stand

- Bee Space™ slipcover and anchorage of the hive

- BeeCozy

- R10 Styrofoam crate

- Combination of R10 Styrofoam and double layered thermofoil

It is important to note that for the BeeCozy slipcover, some elements can be supplemented, such as an insulating cushion for the top of the hive and a special inner cover with a space of about 5 cm where the insulating material can be added (which can be the cushion sold separately).

In September, the colonies were all fed with 24 liters of sucrose syrups 2:1, providing the equivalent of 20 kg of sugar. During the feeding, the colonies were treated against varroasis with Thymovar® (Andermatt BioVet). On October 28th, 2020, the number of beehive frames of each colony was evaluated and a treatment of oxalic acid by dripping was given (35g/L of acid in a sucrose syrup 1:1 at a rate of 5 ml by beehive frame). On November 12th, 2020, the beehives were weighed, pictures of the bottom of the colonies were taken, the HOBO probes and the slipcover were installed. During the winter, the HOBO’s data were downloaded a few times. On April 8th, 2021, the winter slipcovers were taken off and pictures of the bottom of the colonies were taken. On May 12th, 2021, the colonies’ brood surface was evaluated.

For the zootechnical data, a statistical analysis was made by ANOVA with the JMP (SAS, USA) software. Temperature and relative humidity data were analyzed with the HPMIXED procedure of the SAS (SAS, USA) software and the significative differences between the different groups were analyzed with a Tukey test.

Comparative models

Results and discussion

Zootechnical performances:

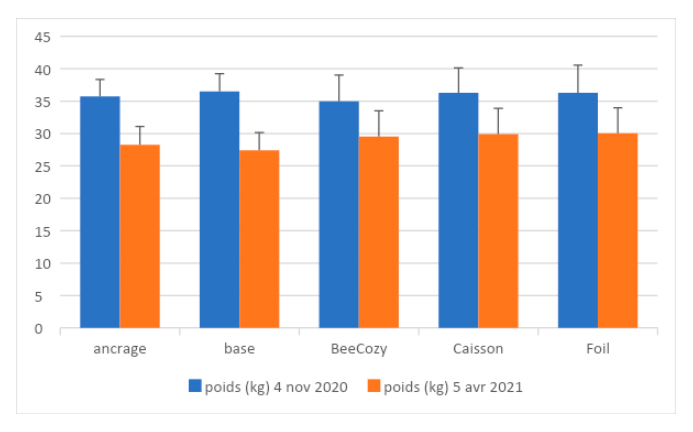

There were no significant differences between the wintering methods for the measured factors. All colonies had similar weight before and after the winter (image 6). When comparing the weight before and after, there was a significative difference only between the Bee Space on a base group and the BeeCozy group (P=0,01). However, the material of the BeeCozy hives group was filled with water during the spring which falsified the weight data and invalidated this difference.

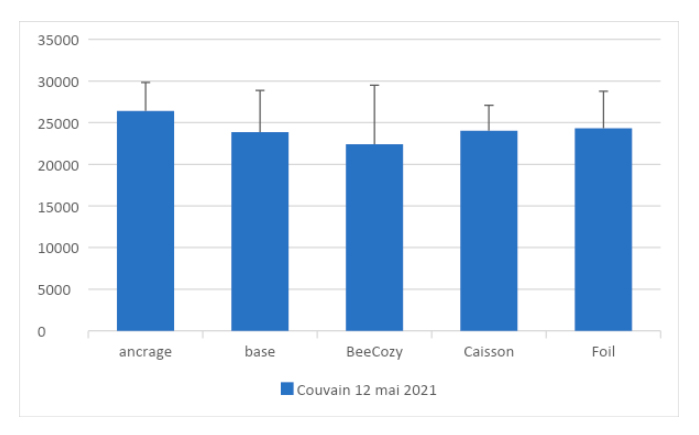

The strengths of the bees were similar before and after wintering (image 7). The spring revival evaluated with the number of brood cells in the colonies was similar between the groups (image 8). Therefore, there was no difference on the survival of the bees and the spring revival between the different types of insulation analyzed. Despite the lack of insulation on top of the 5 BeeCozy colonies group, the zootechnical performances were similar. This demonstrated an excellent hardiness of the CRSAD genetic but complicated the comparison of efficiency between the different methods of winter insulation.

Eight colonies have died during the winter. Five due to a problem with the queen bee, and three have died from starvation, which means that the insulating method did not have any significative impact on the mortality rate of the colonies.

Anchorage: 3 mortalities due to a problem with the queen bee

Base: 1 mortality due to a problem with the queen bee and 1 due to starvation

BeeCozy: 1 mortality due to starvation

Crate: 1 mortality due to a problem with the queen bee

Thermofoil: 1 mortality due to starvation

Installation

All winter slipcovers are easy to install, however, the BeeCozy blocks the entry of the hive. A piece of wood must be installed to lift it and leave room for the bees to enter the hive. Therefore, this requires extra material for the installation and for the storing. The Bee Space™ slipcover with anchorage requires that it be screwed directly on the slipcover, which compromise the material lifespan by creating water infiltration points into the wood.

Durability

During the uncovering process in the spring, we noticed a BeeCozy slipcover had been pierced by a rodent and the material had been filled with water which ruined the slipcover (image 9). A thermofoil slipcover was also completely ripped apart by a skunk in the spring (figure 10). Two of the styrofoam crates showed light damages due to the scratching of a skunk (image 11). All the Bee Space slipcovers were in perfect conditions.

All Bee Space™ slipcovers were in excellent condition.

Dégâts sur produits concurrents

Storing

The styrofoam crates take a lot of storing space, their use is practical in small amount only or they have to be placed on the hives year-round which can bring other problems such as slowing down the spring development (Marceau et Martin 2015) and increase manipulation (opening and closing of the hive). A rigid external layer would have to be added to the crate to make it resistant to multiple manipulations. Other types of slipcovers take up little storing space and those of Bee Space can be stacked more stably.

Humidity

All the wooden equipment of the hives wintering with the BeeCozy is filled with water in the spring. The inner covers and the covers show important signs of mold development (image 12). For the hives without the insulating cushion, it is the cover that is mostly damaged and for those with the cushion, it is the inner cover that is mostly damaged. Without the special inner cover, rainwater or snow melt can infiltrate between the slipcover and the hive. Also, we noticed that the ventilation opening is partially blocked by the slipcover. Some beekeepers put a pipe to allow the evacuation of humidity of the ventilation opening and some even pierce the slipcover to install that pipe. Our results show that to insure an efficient wintering with the BeeCozy slipcover, a inner cover must also be used to prevent water infiltration between the slipcover and the hive and also a pipe or other method must be installed to allow the vent to evacuate humidity.

The styrofoam crates (image 13) and the thermofoil slipcover (image 14) show light condensation at the opening and there are traces of mould on the inner covers. The material of the wintering hives covered with the Bee Space slipcover was dry and free of mould (image 15). The only traces of mould found in the colonies with the Bee Space were under the frames when there were dead bees on the tray and on the envelop (discussed later in this document).

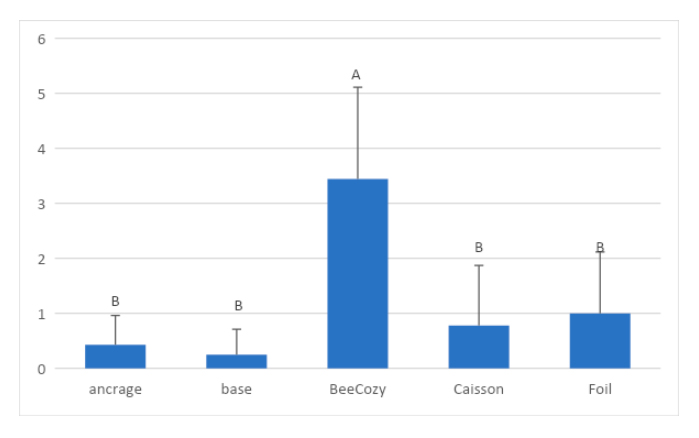

Mold traces - Beehives

When rating the colonies on a scale of 10 for the presence of mould on the hive’s material, the BeeCozy had a bad rating (image 16). The early and dry 2021 spring generated a slight development of mould inside the hives on the tray and under the frames. Colonies are often wintering with a thermofoil slipcover and there is generally more mould than what has been noticed this spring. More regular weather conditions will probably accentuate the performance gap between the Bee Space slipcover, and the other types tested.

The insulating material of the Bee Space slipcover is the only material that allows the hive to release its humidity. However, the outside envelop obstructs that humidity release which creates the development of unwanted mould, compromising the durability of the product (image 17). An alteration of the outside envelop is necessary to allow the release of humidity.

Traces of mold - Hemp insulation

Even though this seems to go against certain concepts of physics related to heat retention, the presence of a vent on the top of the hive to allow humidity release is necessary and does not seem to result into a great heat loss (Anderson 1943). This idea was tested and questioned many times, but the results have never shown a negative impact of the vent on the bee colonies and proved the reduction of mould development on the material (Currie et coll, 2015). This method is now known as the right technique for the outside wintering of the colonies. It is taught and used everywhere. It is also why Bee Space kept using it for their slipcover.

The disposition of the mould in the Bee Space slipcover on the outer membrane instead of on the beekeeping equipment shows that the problem is not the humidity, but the insulating material used. With a waterproof insulating material, the condensation will appear directly on its surface, therefore in contact with the beekeeping equipment. This creates the development of unwanted mould which compromises the durability of the product. Since the insulating material of the Bee Space slipcover allows the release of humidity, a vent hole is not necessary.

An engineer has recently put his knowledge of physics to the use of beekeeping. He did a great popularization in relation this his work in the American Bee Journal of August 2017 (Mitchell 2017). Ironically, the more insulated and ventilated the hive is, the more chances there will be heat loss. He explains that the Anderson experiment (1943) did not detect any heat loss since the temperature of the hot air layer at the top of the hive remained identical but its thickness decreased and the air movement increased with a vent hole. Therefore, there is an important heat loss through the vent hole. With a well-insulated hive, the humidity can’t condense at the top of the hive (Mitchell 2016) and if the insulating material is permeable to humidity, it will not condense on the equipment. The Bee Space slipcover makes the vent hole unnecessary and its retrieval would allow the bee colony to maintain the environmental conditions inside the hive which brings the bees closer to what they are experimenting when they are nesting in nature.

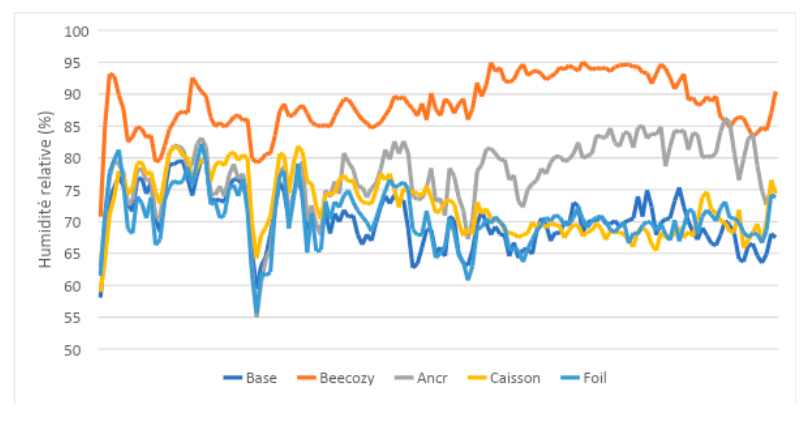

Inside the hive, the BeeCozy group maintained a relative humidity significantly higher than the other groups (image 18). This goes in line with the observations made of the humidity and mould on the equipment presented earlier. The causes listed are the same.

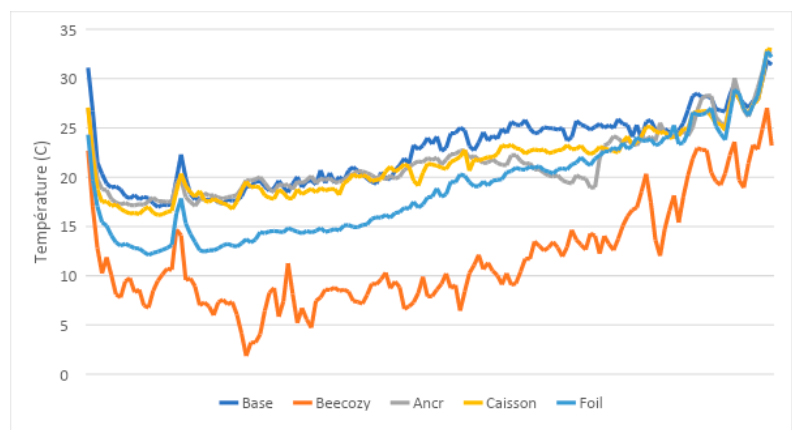

Temperature

The inside temperature of the hive is only significantly inferior for the BeeCozy group (image 19). The other groups are not significantly different despite the tendency of the foil group to have a lower temperature until the coming of spring. The hives with an insulating cushion reach a minimum of 7 oC and those without the cushion reach a minimum of -2oC. This type of slipcover is therefore less high-performance than the other models tested with a minimum of 12 oC for the foil group and 16 to 18 oC for the others.

THI index

The THI (Temperature-Humidity Index) is an index that considers both temperature and humidity. It is an index used to evaluate thermal stress in other livestock production. For example, this index is well categorized in the milk production industry. For bees however, we do not know the limit values to which they will be affected. We are including this index in this report so it can be used as a future reference when more will be known about this subject. For this index, the BeeCozy group is significantly different from the other groups, except from the foil group and there are no other significant differences.

Conclusion

To precisely evaluate the impacts of the different winter insulating methods, we should measure the thickness of the heat dome in the hive and use a less hardy genetic. The Bee Space slipcover is the only slipcover examined that allows humidity release. It is also more durable than the others tested in this evaluation. However, a humidity release method between the insulating material and the slipcover must be created to increase the lifespan of the product. The slipcover makes the use on a vent hole at the top of the hive completely obsolete. This would allow the bees to maintain better environmental conditions and a more important heat dome in the hive. The impact on health, the winter development, and the winter consumption still have to be established, but this product has the potential of improving a centennial method used in beekeeping.

Bibliography

Anderson, E.J. 1943. Some research on wintering bees. Gleanings in Bee Culture. 71:681-683, 715.

Currie, R.W. Spivak, M. et Reuter, G.S. 2015. Wintering management of honey bee colonies. In Graham, J.M. (ed), The Hive and the Honey Bee. Dadant & Sons; Hamilton, IL; pp 629-670.

Marceau, J et Martin, G. 2015. Exploration d’une méthode visant à favoriser le développement printanier des colonies d’abeilles. Rapport de projet; Programme d’appui au développement de l’agriculture et de l’agroalimentaire en région du MAPAQ.

Mitchell, D. 2016. Ratios of colony mass to thermal conductance of tree and man-made nest enclosures of Apis mellifera: implications for survival, clustering, humidity regulation and Varroa destructor. International Journal of Biometeorology 60: 629-638. (doi:10.1007/s00484-015-1057-z)

Mitchell, D. 2017. Honey Bee Engineering: Top Ventilation and Top Entrances. American Bee Journal 157(8): 887-889.